-

Product name:

-

Product description:The coupling diaphragm consists of several groups of diaphragm (stainless steel sheet) which are interlocked with the two..

-

URL:

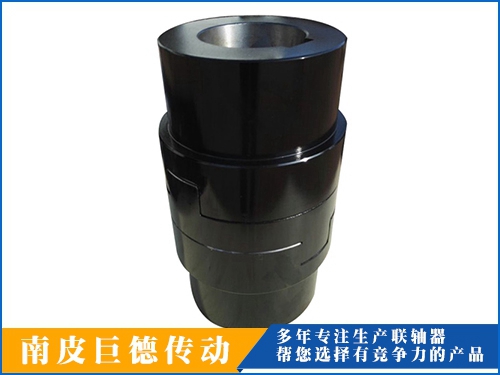

The coupling diaphragm consists of several groups of diaphragm (stainless steel sheet) which are interlocked with the two halves of the coupling by bolts. Diaphragm coupling on the elastic deformation of the diaphragm to compensate for the two axes relative displacement, is a kind of high-performance metal flexible coupling components, no lubrication, structure is compact, high intensity, long service life, no rotating clearance, not influenced by temperature and oil pollution, has the characteristics of acid and alkali corrosion resistance, suitable for high temperature, high speed, working condition of a corrosive medium environment of shaft transmission.

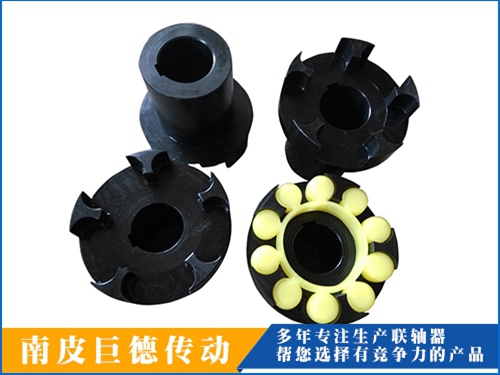

The coupling diaphragm consists of at least one diaphragm and two shaft sleeves. When the diaphragm is fastened to the sleeve with a pin, it will not loosen or cause recoil between the diaphragm and the sleeve. Some manufacturers provide two diaphragms and three diaphragms with one or two rigid elements in the middle and the two sides connected to the bushing. The difference between the single-diaphragm coupling and the double-diaphragm coupling is the difference in the ability to handle various deviations. In view of the need for complex bending of the diaphragm, the single-diaphragm coupling is not suitable for eccentricity. The double diaphragm coupling compensates for eccentricity by bending in different directions simultaneously.

The coupling diaphragm is a bit like a bellows coupling in that it transmits torque in the same way. The diaphragm itself is thin, so it bends easily when relative displacement loads are generated, and thus can withstand deviations of up to 1.5 degrees, while producing a lower bearing load in the servo system. Diaphragm coupling is often used in servo systems. Diaphragm has good torque rigidity, but it is not as good as bellows coupling. Diaphragm couplings, on the other hand, are very delicate and can easily be damaged if misused or not properly installed. Therefore, it is very important to ensure that the deviation is within the normal operating range of the coupling. Choosing the right coupling is the key step to use the coupling well. What type of coupling should be considered in the design stage

With the rapid development of modern industrial technology, the research of high speed and high power rotating machinery has been paid much attention, especially in the dynamics of complex rotor system. The problem of coupling between rotor spans has been widely noticed, which leads to the constant emergence of various new high-performance flexible couplings. The relative displacement of the shaft coupling caused by various factors often requires the use of flexible couplings to compensate. The diaphragm flexible coupling (diaphragm coupling) is one of the new flexible coupling devices.

Diaphragm coupling has many unique advantages, such as high rigidity in torsional direction, high torque transmission, and large deflection in axial and angular directions. It mainly relies on the three-dimensional deformation of the metal diaphragm material to absorb the various (including axial, transverse, angular) deflection of a flexible coupling, and has vibration absorption, shock absorption, especially suitable for high-speed heavy duty occasions.

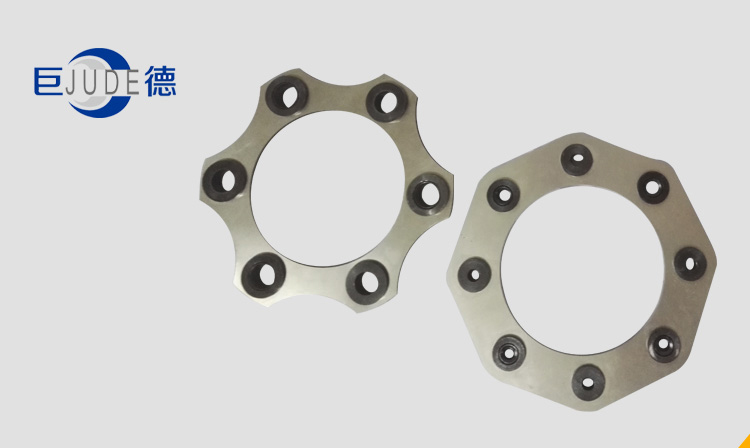

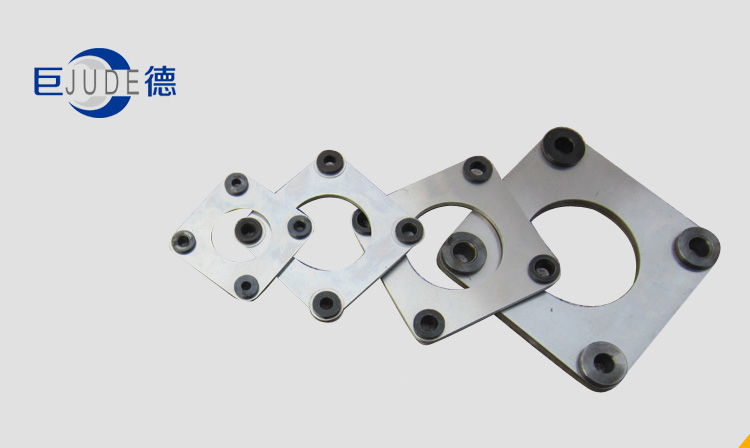

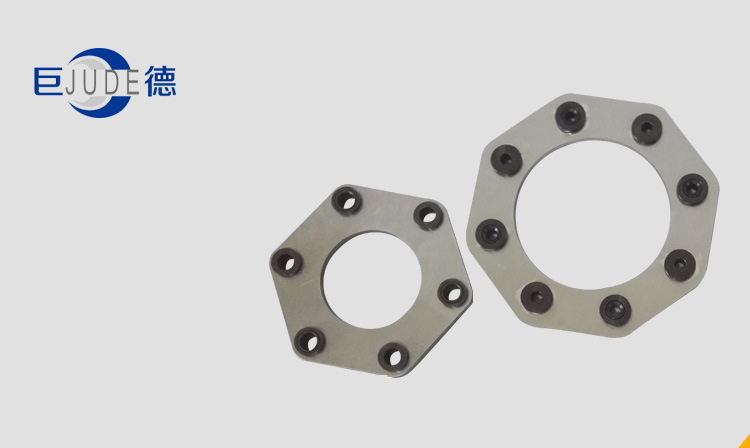

Diaphragm coupling, through which the diaphragm is the key component of the coupling, transmits torque and motion. It is composed of a certain number of thin high-strength alloy plates, with a thickness up to 0.12mm. The main shapes are wheel - width type, ring type, connecting rod type, multilateral type and beam - waist type. The diaphragm used is beam waist type, which has the advantages of close equal strength, good flexibility, low stress around bolt hole and small centrifugal force. The working principle is that the torque is input from the semi-coupling at the active end, transmitted to the diaphragm group through the main transmission torque high-strength bolts arranged along the circumference interval, and then transmitted from the diaphragm group to the output of the semi-coupling at the driven end through the intermediate shaft segment.

江苏Coupling diaphragm 上海Coupling diaphragm

News

News

Internet Content Provider:冀ICP备18017241号-1

Copyright © 2019 - 2020 jude transmission All Right Reserved.